Quick summary

- Metal fabricators can use job tracking software to check the status of individual tasks or entire projects

- Job tracking software helps manufacturers save both time and money through efficiency gains, visibility into costs and data-driven decision making

- MIE Trak Pro is an ERP with job tracking functionalities, so businesses can automate tracking and allocate resources efficiently

As a metal fabricator, you’re constantly working against the clock, which means you need to be able to track components on the shop floor without delay and see live job statuses. U.S. fabricators are increasingly turning to automation to stay competitive – and job tracking software enables you to automate manual processes and work smarter.

In this article, we’ll look at how job tracking software can be used in metal fabrication businesses, including the areas where it can help you save time and money.

What we’ll cover

What is job tracking software?

What is one of the best job apps?

Five ways job tracking software saves time and money

How can metal fabricators use job tracking software

How to choose reliable job tracking software

Digitize the job tracking process

What is job tracking software?

Job tracking software provides visibility into your projects from start to finish, so you can see the progress of specific tasks and entire projects. It’s a major step up from spreadsheets and outdated paper-based tracking because you can get real-time data to make fast and informed decisions.

The software allows planning teams to send jobs directly to the shop floor, so members of the production team can instantly view their tasks and update them on the go, marking them as complete, incomplete or a work in progress (WIP). The location of every product can also be updated and you’ll receive helpful insights such as labor, time and money spent on each task.

Job tracking software is an important part of a good enterprise resource planning (ERP) system and gives you a real-time view of job status and the resources required to fulfil orders.

What is one of the best job apps?

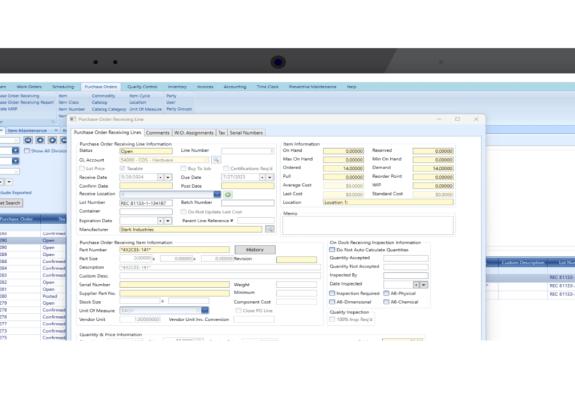

MIE Trak Pro, which is an ERP designed for discrete manufacturers, offers all the benefits of an ERP – but goes a step further with job tracking by allowing users to check the availability of machines and track labor.

How can MIE Trak Pro help?

Work order tracking: It starts with a digital tracking system for all work orders, so planning teams can automatically generate work orders and assign them to the right person. It has a user-friendly interface, enabling team members to view tasks and easily update statuses and location. This also includes useful data such as the time spent on a project and materials costs.

Kiosk: Metal fabricators can add Kiosk to their ERP – a workstation application that’s available via a desktop or website, and accessible on a mobile. It allows staff to clock in and out, see the production schedule for jobs and machines, and view, release or complete work orders on the go. You can request maintenance or inspections and message other team members too.

Labor tracking: A whiteboard scheduling function makes it easy for planning teams to allocate jobs and check the availability of machines to prevent idle time. The ERP allows you to nest together different work orders, so that machines can be used efficiently, and provides valuable insights like employee productivity and inventory status, which should reduce bottlenecks and downtime.

Five ways job tracking software saves time and money

With reliable job tracking software, metal fabricators can make sure that jobs are completed on time – and orders fulfilled – while keeping on top of costs.

Real-time visibility

An ERP saves significant time since your team won’t have to physically look for products/parts on the shop floor – and you can cut down on status meetings and handovers because everyone can track the job to see where it’s located and how it’s progressing.

The software provides updates on time spent on the task, so if a job is behind schedule, you can act quickly and allocate more resources to it. Since you can quickly update the schedule too, you’ll reduce admin time.

Better cost control

With each task or project, you’ll be able to view costs such as materials or labor, which supports accurate quoting [link to quoting software article]. It helps to track whether each task is within budget or if there are any opportunities to trim costs. Use the financial data to make informed decisions – for example, if a task is labor intensive and costly, you could invest in automation or specialist machinery to speed it up in the future.

By improving overall efficiency with job tracking software, metal fabricators can improve both their capacity to take on more orders, their revenue and their profits.

Going paperless

Using an ERP speeds up processes like tracking or allocating tasks can be done within minutes. All the critical data is stored in the system with access control, so employees can access information related to their role and make a quick start on jobs. Overall, there is less administration work and a lower risk of making expensive mistakes because all the data is kept up to date in a single system.

Smarter scheduling

Scheduling can be complex, especially if you have bigger orders and teams. Job tracking software makes the task easy – you simply drag-and-drop tasks to the right team member. You can also set jobs based on machine availability, so employees aren’t waiting around for equipment to become available, while schedules can be immediately updated based on the urgency of the task.

Informed decision making

Guided by trusted data,you’ll make smarter decisions that save time and money. For example, if your insights show a job is taking longer to complete, you can focus on optimizing that process. With MIE Trak Pro, you’ll get a fully-integrated reporting system that generates reports using data such as sales or production in seconds. The reports can be customized or edited as you view them, saving time.

How can metal fabricators use job tracking software?

The best job app should make your teams day-to-day easier and help you better manage production. It offers time and cost savings to metal fabricators who use it to:

- Find where items are located

- Track time, costs and labour allocated to each task

- Send digital work orders

- Manage employees tasks

- Keep order statuses up to date

- Schedule machines

- Calculate quotes more accurately

- Automate reporting

- Reduce idle time

- Make data-driven decisions

How to choose reliable job tracking software

A good job tracking software should be part of your ERP to ensure data is current and consistent across your business. Here are some important factors to consider.

Will it support your digitization goals?

Job tracking software helps you become more competitive with automated functionalities such as reporting and work orders. A slow, clunky system will do the opposite, limiting your opportunities to modernize and grow.

Look for software that is easy for everyone to use. For example, MIE Trak Pro, has a visual dashboard to get insights fast and drag-and-drop functionalities for scheduling.

Does it have a web application?

A web application – where software is available via a browser – makes software easy to use. In the context of job tracking software, it means teams can update tasks on the go or view jobs no matter where they are on the shop floor. The ease of use means staff are more likely to input the correct information, which improves your data quality.

Can you manage and track labor?

MIE Trak Pro is one of the best ways to track employees’ tasks because you can schedule both labour and machines accurately and update it when tasks change. Managers simply assign work orders to specific employees – or split them up – ensuring the right task is with the right skilled labourer. Tasks are automatically available on the desktop or web application, so your teams know exactly what they need to do, saving time and increasing productivity.

What is the reporting function like?

Manual reporting can take hours or even days, but a good job tracking system includes automated reporting for different processes like production or finance, so you can respond to demand quickly and make fast decisions. MIE Trak Pro has 500 standard templates to create reports – or 200 quick view reports, which are ideal for the shop floor where you need information instantly. It saves you time looking through various documents and modules.

When looking for new job tracking software, check the credentials of the software provider, and testimonials and case studies.

Digitize the job tracking process

Manual job tracking can take hours and is error prone, especially if you’re relying on paper-based systems or spreadsheets. In effect, it’s a waste of time. Instead, implement a digital job tracking system like MIE Trak Pro to automate processes like status checks with instant visibility into tasks and more efficient resource allocation.