For job shops and manufacturing businesses, selecting the right job shop software presents a significant challenge. With hundreds of different ERP systems on the market today, the decision becomes even more complex when you consider the financial stakes involved—implementation costs start at $20,000 and monthly user fees average $200.

The cost of choosing the wrong system can impact your operations for years. However, manufacturers who select the right ERP solution see real value, with retention rates reaching 97%. Machine shop ERP software has become essential for businesses looking to remain competitive in today’s market.

What makes this decision particularly challenging? Each manufacturing environment has unique requirements. Your custom fabrication shop operates differently from a precision machining business, yet both need software that can handle complex scheduling, accurate job costing, and real-time production tracking.

As part of a metalworking community that includes more than 200,000 registered members, we understand the specific challenges you face when evaluating job shop management software options. The questions that keep you up at night: Will this system grow with my business? Can it handle our complex scheduling requirements? Will my team actually use it?

This job shop software comparison examines seven leading ERP solutions designed specifically for manufacturing environments. We’ll explore pricing models, core features, deployment options, and scalability considerations—giving you the information needed to make a decision that aligns with your operational requirements. Whether you manage a small custom fabrication operation or a growing precision machining business, you’ll discover which job shop ERP software delivers the best return on your investment.

Top 6 Job Shop ERP Software Compared

Each job shop ERP system addresses specific manufacturing challenges with distinct capabilities. The following solutions represent the market leaders, each designed for different operational environments and business scales.

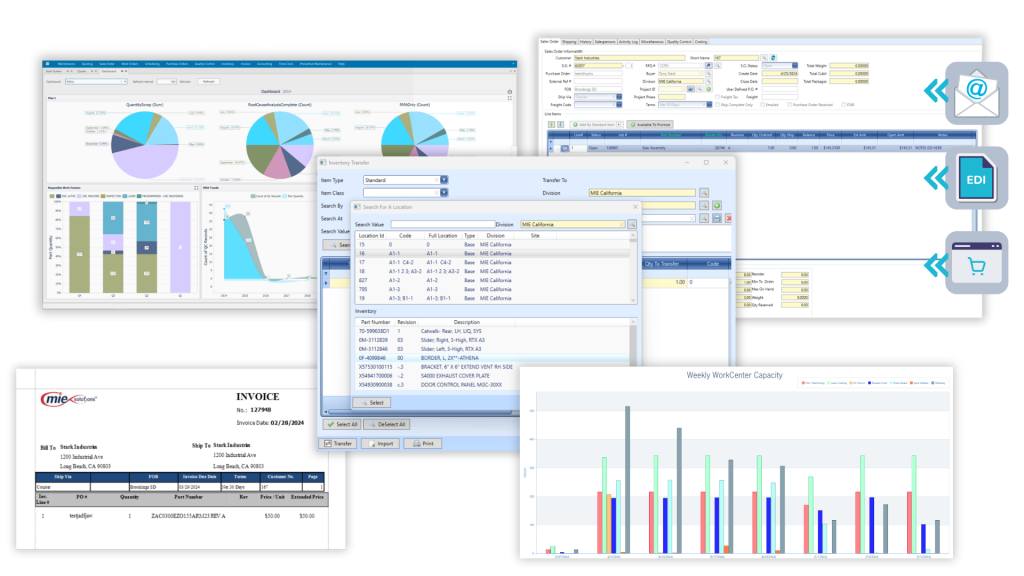

1. MIE Trak Pro: Leading ERP for Job Shops and Discrete Manufacturers

Manufacturing companies choose MIE Trak Pro for its exceptional flexibility in managing workflows from initial quote through final delivery. The system’s quoting functionality allows you to personalize formulas and create quotes based on true costing data, eliminating guesswork from your pricing decisions.

MIE Trak Pro adapts as organizations grow, balancing departmental flexibility with administrative control. This scalability proves essential when your small shop evolves into a multi-department operation requiring different levels of system access and functionality.

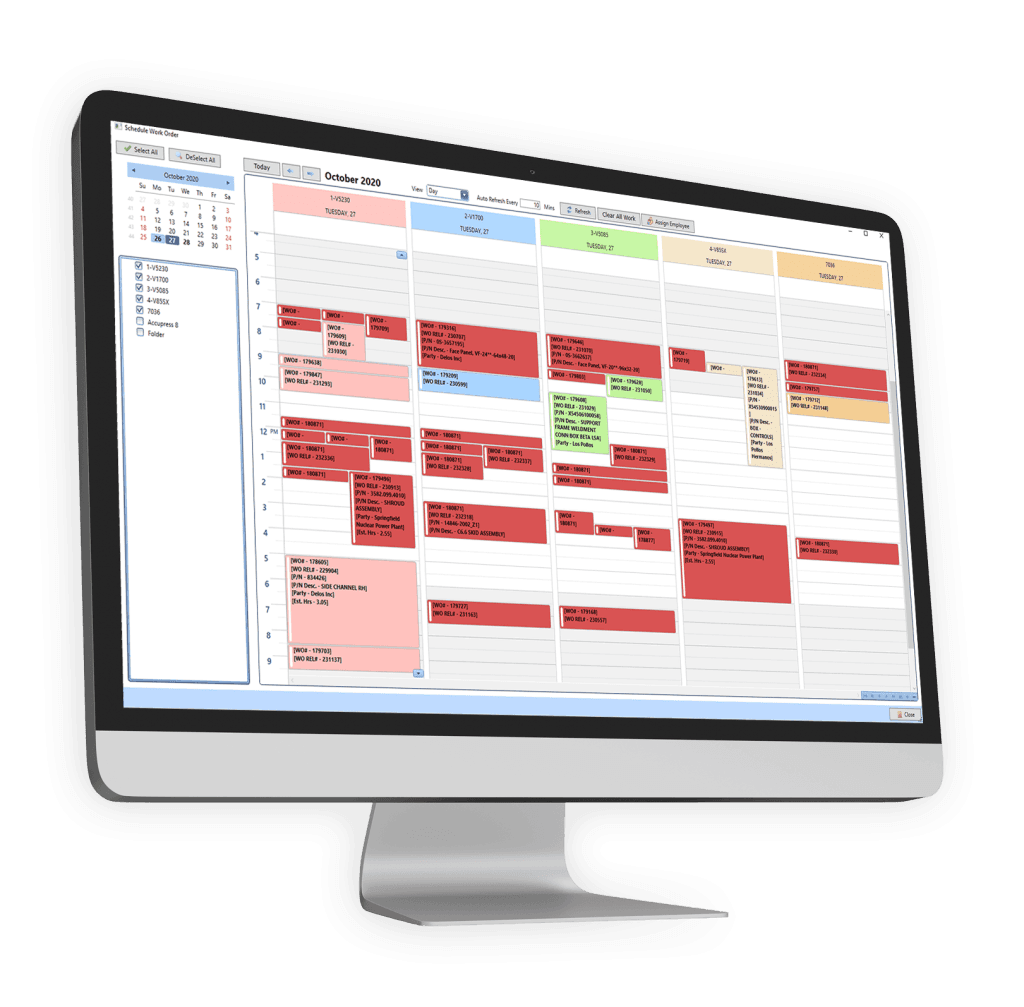

Production planning becomes strategic rather than reactive with multiple scheduling methods—forward finite, backward infinite, and drag-and-drop functionality optimize resource allocation while preventing bottlenecks. Users report substantial efficiency gains, with some documenting a 30% improvement in shop floor productivity due to enhanced visibility.

2. ProShop ERP: Paperless Manufacturing Management

ProShop ERP eliminates paper-based processes through a fully digital manufacturing environment. This web-based system connects every aspect of your operation with unified workflows built specifically for manufacturing.

The business impact becomes apparent quickly. Users implementing ProShop have cut audit preparation time by 96% and reduced scrap to 0% on first-part runs. The system provides media-rich, step-by-step instructions that reduce errors by up to 90% and cut onboarding time in half.

Most shops successfully implement ProShop within just a few weeks, with pricing based on the number and type of users needed. This rapid deployment minimizes disruption to ongoing operations.

3. MRPeasy: Lightweight ERP for Discrete Manufacturing

Smaller operations find MRPeasy delivers streamlined manufacturing management without overwhelming complexity. This lightweight solution enables users to manage simple assemblies or highly complex products with equal efficiency.

Companies implementing MRPeasy frequently report significant capacity improvements, with some noting their production capacity doubled after adoption. The system offers excellent integration capabilities, working seamlessly with Xero and Shopify to create a connected business ecosystem.

More than 2,000 manufacturers choose MRPeasy for its balance of user-friendliness and powerful functionality. This widespread adoption reflects the system’s ability to deliver enterprise-level capabilities at a scale appropriate for growing operations.

4. DELMIAWorks: ERP + MES for Mid-Market Manufacturers

Mid-market manufacturers benefit from DELMIAWorks’ combination of robust ERP capabilities with integrated Manufacturing Execution System functionality in one native solution. Originally developed as IQMS, this platform provides real-time production monitoring and shop floor visibility.

The system creates a digital thread enabling cross-functional collaboration across the entire business. For specialized operations like plastic injection molding, DELMIAWorks excels with its RealTime Process Monitoring System that collects live data on key performance indicators like temperature and pressure.

5. Fishbowl: Inventory-Centric ERP for Job Shops

Fishbowl addresses the inventory management challenges that plague many job shops, particularly excelling for sheet metal fabricators. The system serves as a comprehensive inventory solution that acts like an ERP when connected with accounting, shipping, and CRM systems.

Fishbowl automatically generates insightful reports on sales trends, enabling better inventory allocation and purchasing decisions. Its seamless integration with QuickBooks makes it ideal for shops seeking to enhance inventory management without replacing existing accounting software.

6. Infor VISUAL: Throughput-Focused ERP for Custom Shops

Order-driven manufacturers choose Infor VISUAL for consistently profitable results through enhanced production throughput. Its patented scheduling tools provide complete visibility of work schedules in a paperless environment.

The system excels at identifying potential resource and material bottlenecks through reliable audit trails. For custom manufacturing operations, VISUAL’s Manufacturing Window graphically represents build structures, becoming the catalyst for accurate material planning and production scheduling.

Users particularly value its ability to perform “what-if” capacity checks for determining potential new order delivery dates. This capability proves essential when evaluating whether to accept rush orders or commit to aggressive delivery schedules.

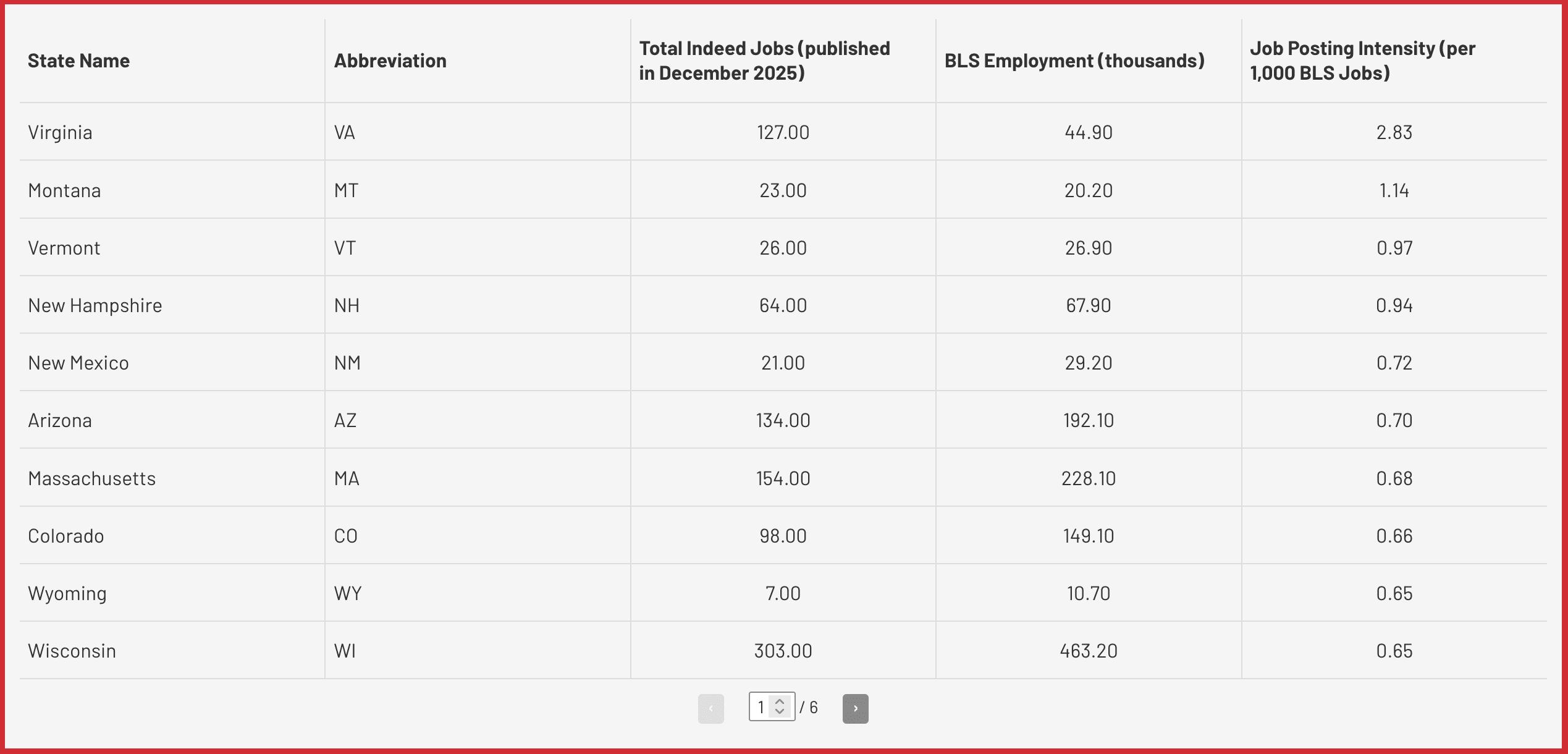

Feature Comparison by Manufacturing Needs

Your manufacturing operation faces unique challenges that generic software simply cannot address. Selecting the right job shop ERP requires understanding how each solution handles the specific operational needs that drive your daily decisions.

Inventory Tracking and BOM Management

Bill of Materials (BOM) management forms the foundation of efficient manufacturing operations. Without accurate BOM data, your production planning becomes guesswork, leading to material shortages, cost overruns, and missed delivery dates.

A comprehensive BOM acts as a blueprint that includes all raw materials, subassemblies, and parts required to create finished products. Job shop software with robust BOM capabilities enables manufacturers to maintain multi-level BOMs that track every component from raw material to finished product. Version control features prevent production errors by tracking changes in designs and component specifications.

The most effective systems support different BOM types tailored to specific departmental needs:

– Engineering BOMs (eBOMs) for design purposes – Manufacturing BOMs (mBOMs) for production

– Service BOMs (sBOMs) for maintenance and repair

This differentiation eliminates confusion between departments while ensuring everyone works from accurate data. Advanced BOM software also provides real-time inventory tracking across multiple locations, automated replenishment based on stock thresholds, and batch/lot management for improved traceability.

Job Costing and Scheduling Capabilities

Accurate job costing remains one of the most challenging aspects for custom shops. How do you ensure profitability when every order involves different materials, processes, and labor requirements?

Complete job costing software tracks all costs associated with manufactured items, including materials, labor, equipment usage, and outsourced operations. The most effective systems allow manufacturers to break down costs by FLOOOM components (Freight, Labor, Overhead, Outside Services, Other, and Material).

Advanced job costing modules enable manufacturers to compare actual costs against estimates throughout project phases. This capability helps identify inefficiencies and improve pricing decisions for future jobs. Real-time job costing lets shops improve on the fly and better predict profit margins.

For scheduling, leading ERPs offer multiple methods including forward finite, backward infinite, and drag-and-drop functionality to optimize production planning. These tools help prevent bottlenecks while balancing available resources with forecasted demand and delivery commitments.

CAD Integration and Drawing Management

CAD integration eliminates manual data re-entry from design systems into your ERP. Without integration, engineers or clerks spend hours transferring Bills of Materials by hand, creating duplicate work. Properly integrated CAD-ERP systems allow data to flow directly from design to production through automatic BOM creation and real-time part number synchronization.

Key capabilities include bi-directional synchronization between CAD and ERP, instant generation and updates of BOMs, and linking drawings to part numbers and jobs. These features accelerate engineering-to-production cycles, with designs moving from engineering to shop floor in hours rather than days.

Mobile Access and Real-Time Data Collection

Mobile ERP applications extend functionality beyond office computers to smartphones and tablets on your shop floor. These tools provide real-time access to manufacturing data from anywhere, allowing employees to make immediate decisions with direct impact. Mobile capabilities enable faster decision making, improved communication, and greater operational efficiencies.

Core mobile functions include inventory management, purchase order control, and work order processing directly from the shop floor. This immediate access to data helps manufacturers track production in real-time, detect issues earlier, and reduce downtime.

Quality Control and Compliance Features

Quality management modules help manufacturers meet product standards while maintaining regulatory compliance. These features pinpoint inefficiencies and identify areas for quality improvement. Advanced quality control systems offer comprehensive quality testing, automatic defect flagging, ongoing lot tracking, and automated compliance documentation.

For regulated industries, robust compliance capabilities include centralized data management, automated audit trails, and real-time monitoring with alerts. Batch and lot tracking provides complete forward and backward traceability—essential for recall management and regulatory reporting requirements. Electronic signature capabilities eliminate paper-based processes while maintaining compliance with FDA requirements.

Deployment Models and Platform Compatibility

Your deployment choice affects more than just where your software runs—it impacts daily operations, costs, and your team’s ability to access critical manufacturing data. Understanding these options helps ensure your ERP investment delivers value throughout its operational life.

Cloud vs On-Premise: Making the Right Choice for Your Shop

Cloud-based ERP solutions continue gaining momentum, with 31% of businesses already using SaaS deployment models and 51% planning to move in this direction. For job shops, this decision shapes how your team interacts with the system every day.

Cloud ERP Benefits:

- Lower upfront investment requirements

- Faster implementation timelines (typically 3-6 months versus 12+ months for on-premise)

- Automatic updates and maintenance included

- Remote accessibility for distributed teams

- Total cost of ownership reduced by 30-50% over five years compared to on-premise deployments

Recent workflow disruptions proved cloud accessibility invaluable for manufacturing teams needing system access from multiple locations.

On-Premise Benefits:

- Complete data control and security oversight

- Potentially lower long-term costs for larger operations

- Independence from internet connectivity requirements

- Preferred option for highly regulated industries like defense or aerospace

Which approach fits your operation? First-time ERP buyers typically find cloud options more accessible due to lower barriers to entry. However, shops with established IT infrastructure and specific security requirements might benefit from on-premise deployment.

Mobile Applications for Real-Time Shop Floor Management

Mobile capabilities extend your ERP beyond the office, enabling immediate decision-making where production happens. Most modern job shop software includes mobile functionality, though capabilities vary significantly.

DELMIAWorks mobile ERP brings manufacturing data directly to smartphones and tablets, providing instant access to work center productivity metrics, current production efficiency, scrap rates, and downtime tracking. These applications offer two-way data interaction—not just viewing information, but making operational adjustments in real-time.

MIE Trak Pro offers users Kiosk, an integrated mobile experience giving users access to manufacturing data on the fly. Kiosk offers your team access to scheduling, clocking in and out abilities, quality control and much more. These mobile capabilities are essential in today’s fast paced and flexible manufacturing environments.

Platform support generally includes both iOS and Android, though Android receives more widespread support among manufacturing ERP vendors. Before selecting your system, verify mobile functionality works with your existing devices.

Operating System Compatibility Considerations

Platform flexibility matters when your shop uses mixed computing environments. Legacy ERP systems were built exclusively for Windows, but newer web-based solutions provide cross-platform compatibility.

Several job shop software solutions function across all major operating systems. Bizowie delivers complete functionality—including financials, manufacturing, and distribution—for any platform with a web browser, supporting Mac, Windows, and Linux. This approach eliminates vendor lock-in to specific operating systems.

Open-source alternatives like ADempiere, Odoo, and Tryton operate across multiple platforms, with ADempiere accessible on Linux, Unix, Windows, MacOS, smartphones, and tablets. This flexibility allows hardware choices based on your preferences rather than software limitations.

Pricing Models and Licensing Options

Understanding pricing structures for job shop ERP systems directly impacts your long-term return on investment. Two distinct licensing models dominate the market, each carrying unique financial implications for manufacturers.

Monthly Subscription vs One-Time License

The subscription model (SaaS) requires recurring monthly or annual payments for software access, hosting, and support. This approach demands lower upfront investment compared to perpetual licensing, making it particularly attractive for smaller operations with limited initial budgets.

Perpetual licensing involves a one-time payment for indefinite software ownership plus a smaller annual maintenance fee. While perpetual licensing requires substantial initial capital, it often delivers lower total costs over extended periods—typically beyond five years of use.

Growing shops benefit from subscription models through scalability advantages—you can adjust user counts as your needs evolve. However, these recurring costs accumulate over time, potentially surpassing perpetual license expenses for established operations.

Minimum Implementation Fees and Hidden Costs

Implementation expenses typically equal 100-200% of annual software fees. For mid-sized operations, this translates to approximately USD 8,542.00 per user over five years. Beyond licensing, prepare for costs including:

– Data migration (USD 25,000.00-150,000.00)– Training (USD 5,000.00-75,000.00)

– Customization (USD 50,000.00-500,000.00+)– Infrastructure upgrades for on-premise deployments

Financial experts recommend adding a 10-40% contingency fund to your initial budget to protect against unexpected expenses. While ERP implementation requires careful planning and investment, the risks of not implementing a system can far outweigh the initial costs.

Choosing the Right ERP Based on Shop Size

Business size dictates appropriate ERP selection—different solutions match specific operational scales and complexity levels. Your machine shop’s current size and future growth trajectory should drive the selection process to maximize return on investment.

Small Shops Need Focused Solutions (1–20 Employees)

Small job shops face unique challenges that larger manufacturers rarely encounter. With limited IT resources and tight budgets, you need systems that work immediately without extensive customization or training.

Cloud-based solutions minimize infrastructure demands while providing the accessibility your growing operation requires.

For small manufacturers, integration capabilities matter more than extensive feature sets. Since 67% of small businesses already use accounting software like QuickBooks, systems like MIE Trak Pro excel by offering seamless accounting connections without forcing you to replace existing financial systems.

Key considerations for small shops:

- Prioritize systems with established integrations over custom development

- Choose cloud deployment to avoid infrastructure costs

- Focus on core manufacturing functions rather than extensive modules

Mid-Size Operations Require Greater Complexity (20–100 Employees)

Once your operation grows beyond 20 employees, your ERP requirements expand significantly. Mid-sized manufacturers typically need systems supporting 20-100 users with deeper functionality across multiple departments.

At this scale, departmental coordination becomes critical. Your estimating team needs access to real-time production data, while your shop floor supervisors require inventory visibility.

Mid-market manufacturers often serve regulated industries requiring robust quality control and compliance features. Unlike small shops that can operate with basic tracking, mid-sized operations need comprehensive audit trails and documentation capabilities.

Growth Planning Prevents Costly Migrations

The most expensive ERP decision you can make? Choosing a system that can’t grow with your business.

Examine user licensing flexibility first—scalable ERPs accommodate growth without forcing complete system changes. Cloud-based solutions typically offer better scaling options, with implementation costs typically 30-50% lower than on-premise alternatives.

Modular systems provide the most flexibility for growing shops. Start with core modules like job costing and scheduling, then add capabilities like quality management and advanced reporting as operations expand. This approach spreads costs over time while ensuring each new module addresses specific business needs as they arise.

The alternative—migrating to a new system every few years—costs far more than investing in scalable software from the start.

Conclusion

Selecting job shop software requires more than comparing features and prices—you need a system that aligns with how your manufacturing operation actually works. Each ERP solution we examined addresses different operational challenges, from basic inventory tracking to advanced scheduling and quality control.

Your shop size and growth trajectory determine which approach makes the most sense. Small operations benefit from lightweight, cloud-based systems that don’t require extensive IT infrastructure. Growing manufacturers need scalable solutions that can expand functionality without forcing complete system replacements. Established shops often require comprehensive platforms that integrate deeply with existing processes.

The decision comes down to matching software capabilities with your specific manufacturing environment. Job shops handling complex, made-to-order production need robust scheduling and job costing features. Sheet metal fabricators require strong CAD integration and material tracking. Regulated manufacturers must prioritize compliance and quality management modules.

Implementation success depends on choosing software built for your industry. Generic business systems lack the manufacturing-specific functionality that makes job shop operations efficient. ERP systems designed by manufacturers for manufacturers understand the unique challenges you face daily—from managing rush orders to optimizing shop floor schedules.

The right ERP system transforms how your manufacturing operation functions. Better visibility into production schedules, accurate job costing, and streamlined workflows directly impact profitability and customer satisfaction. Most importantly, you gain the operational foundation needed to grow your business without being constrained by inadequate systems.

Which system fits your manufacturing needs? Consider your operational requirements, evaluate deployment options that match your infrastructure, and choose software that can scale with your growth plans. Your job shop deserves an ERP solution that enhances efficiency while supporting the unique demands of discrete manufacturing.

Key Takeaways

Choosing the right job shop ERP software requires careful evaluation of your specific manufacturing needs, budget constraints, and growth plans. Here are the essential insights to guide your decision:

• Size-based selection matters: Small shops (1-20 employees) benefit from lightweight solutions, while mid-size operations need comprehensive systems like MIE Trak Pro.

• Implementation costs are substantial: Budget 100-200% of annual software fees for implementation, with total costs reaching $8,542 per user over five years including training, data migration, and customization.

• Cloud vs on-premise impacts ROI: Cloud solutions reduce total cost of ownership by 30-50% over five years and offer faster implementation (3-6 months vs 12+ months), making them ideal for growing shops.

• Feature priorities drive value: Focus on core manufacturing needs like BOM management, job costing, CAD integration, and mobile access rather than getting overwhelmed by extensive feature lists.

• Scalability prevents costly migrations: Choose systems that can grow with your operation through modular expansion and flexible user licensing to avoid expensive system changes as you scale.

With 97% retention rates among manufacturers, investing in the right ERP system clearly delivers long-term value when properly matched to your operational requirements and growth trajectory.

FAQs

Q1. What are the key factors to consider when choosing job shop software? When selecting job shop software, consider your shop size, specific manufacturing needs, budget, deployment preferences (cloud vs. on-premise), and scalability requirements. Also, evaluate features like inventory tracking, job costing, scheduling capabilities, and quality control.

Q2. How much does job shop ERP software typically cost? Job shop ERP software costs vary widely. Monthly subscriptions can range from $49 to $715 per user, while implementation fees typically equal 100-200% of annual software costs. Total costs over five years can reach around $8,542 per user, including training and customization.

Q3. What are the advantages of cloud-based ERP solutions for job shops? Cloud-based ERP solutions offer lower upfront costs, faster implementation (3-6 months), automatic updates, and reduce total cost of ownership by 30-50% over five years compared to on-premise systems. They also provide better accessibility and scalability for growing operations.

Q4. How important is mobile access in job shop software? Mobile access is crucial for modern job shops. It enables real-time data collection and decision-making on the production floor, improving efficiency and communication. Most modern job shop software offers mobile capabilities for both iOS and Android platforms.

Q5. What features should small job shops prioritize in ERP software? Small job shops (1-20 employees) should prioritize lightweight, affordable systems with streamlined functionality. Key features to look for include QuickBooks integration, basic inventory management, simple job costing, and cloud-based deployment to minimize IT infrastructure demands.