For process manufacturers, generic ERP solutions fall short. Your formulation and batch processes demand specialized tools that deliver precision, compliance, and control.

MIE Solutions offers purpose-built Process Manufacturing ERP that transforms operations while adapting to changing market demands.

Process manufacturing challenges require specialized solutions:

– Recipe Management: Ensure consistency across batches

– Regulatory Compliance: Meet industry requirements

– Complete Traceability: Track materials through production

– Yield Optimization: Maximize output while maintaining quality

Without specialized ERP, you risk quality issues, compliance violations, and diminished profitability.

Save time and increase the accuracy of estimating with MIE Trak Pro’s quoting functionality which allows you to personalize formulas, track win/loss, and create quotes based on true costing data.

Learn more

Take your quote and create a Sales Order in just a few clicks. Sales Orders can be created from an RFQ, Quote, PDF, EDI, and more—depending on your team’s workflow.

Learn more

Gain insights into your production environment with MIE Trak Pro’s Work Order module. See all the information you want related to production in real-time.

Learn more

Schedule production quickly and accurately with forward finite, backward infinite, and calendar-based drag-and-drop scheduling. Take the guesswork out of scheduling employees and machines to jobs.

Learn more

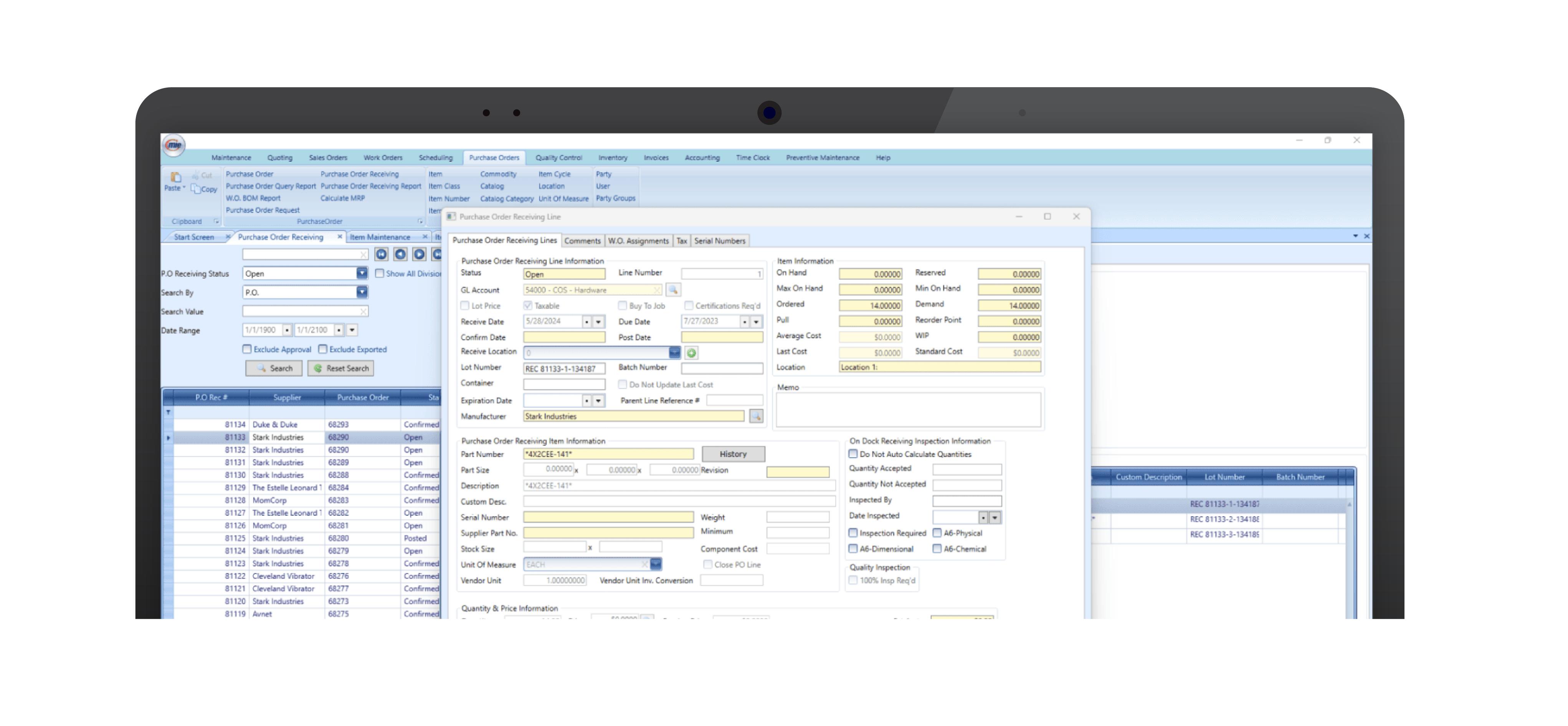

Make purchasing easy and efficient with MIE Trak Pro’s Purchasing module. Order material based on MRP forecasting, min/max reorder points, production demand, and more.

Learn more

Track your inventory and the information that matters to you, including lot number serialization, locations, remnants, WIP, non-netted, consignment, and more.

Learn more

MIE Trak Pro’s built-in quality management system (QMS) allows you to accurately track Corrective and Preventive Action Requests (CPAR), non-conformance, RMAs, and more to pass QC audits with ease.

Learn more

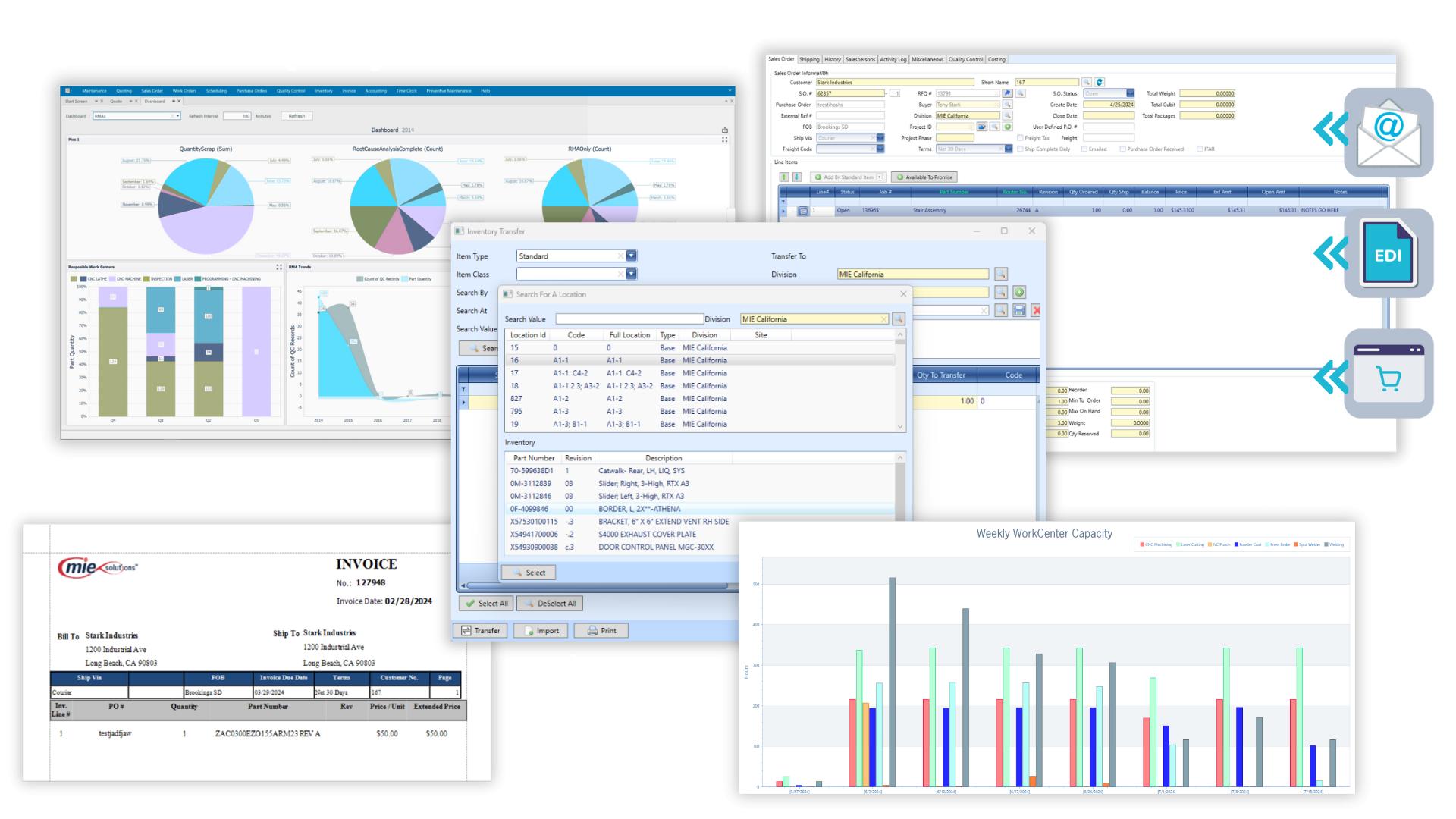

Drive intelligent business decisions by using any of MIE Trak Pro’s standard reports or create personalized queries to get answers to the questions most important to you.

Learn more

Use MIE Trak Pro’s Kiosk module to track real-time job progress and employee clock-in (without the need for paper timesheets). Shop floor employees can see their schedule, view documents, issue material to jobs, create PO requests, and more.

Learn more

Integrate your accounting practices through MIE Trak Pro. Manage G/L Accounts, journal entries, reports, and cash flow projections, in addition to other critical accounting capabilities.

Learn moreMetro Metal Works streamlined quoting and boosted job wins to 90% with MIE Trak Pro.

Cardinal MetalWorks quadrupled revenue and tripled headcount after switching to MIE Trak Pro.

Hansen Industries improved on-time delivery to 97% and integrated quality tracking across their shop with MIE Trak Pro.

Successful Solutions

See just how powerful MIE Trak Pro is by going on a software tour with one of our experts. We’d be happy to show you around, answer your questions, and most importantly, make sure MIE Trak Pro is the best fit for your business.

In today’s competitive manufacturing landscape, having the right technology infrastructure isn’t just an advantage—it’s essential for survival. Process manufacturing ERP software represents the backbone of modern manufacturing operations, particularly for businesses that transform raw materials through chemical reactions, formulations, or recipes into finished products.

Unlike discrete manufacturing, where distinct components are assembled into finished products, process manufacturing presents unique challenges that require specialized solutions. Manufacturing software ERP systems designed specifically for process industries must handle:

When evaluating manufacturing ERP softwares, process manufacturers must ensure these specialized capabilities are central to the system, not afterthoughts or add-ons.

While many industries utilize process manufacturing ERP software, certain sectors face particularly complex challenges:

Chemical Manufacturing ERP Software must handle hazardous materials tracking, environmental compliance, and complex quality testing protocols. Chemical producers rely on these systems to maintain safety while optimizing production efficiency.

Food & Beverage Producers depend on manufacturing pro ERP systems to manage allergen tracking, nutritional calculations, and lot traceability to ensure consumer safety and regulatory compliance.

Pharmaceutical Manufacturers require validation-ready systems with electronic batch records, stability testing, and complete chain of custody documentation.

Cosmetics & Personal Care businesses use process manufacturing ERP solutions to manage formula variations, stability testing, and international compliance requirements.

When evaluating visual manufacturing ERP software for your process industry, prioritize these essential capabilities:

Successfully implementing manufacturing ERP software requires careful planning and execution:

When properly implemented, process manufacturing ERP solutions deliver significant returns:

Q: What’s the difference between process manufacturing ERP and discrete manufacturing ERP?

A: Process manufacturing ERP software manages formula-based production where materials are transformed through chemical processes or recipes, often in batches. Discrete manufacturing ERP handles assembly of distinct components into finished products. Process systems must manage batch production, ingredient variability, and complex quality testing.

Q: How does process production ERP handle recipe management?

A: Modern process manufacturing ERP solutions provide dedicated formula management modules that maintain version control, scale quantities automatically, calculate costs based on ingredient prices, manage substitutions, and ensure quality parameters are met with each production run.

Q: Can manufacturing software ERP systems integrate with laboratory information management systems (LIMS)?

A: Yes, leading process manufacturing ERP solutions offer integration capabilities with LIMS to streamline quality testing, automatically update material specifications, and maintain comprehensive test records throughout the production process.

Q: How does chemical manufacturing ERP software handle regulatory compliance?

A: Chemical manufacturing ERP systems include specialized functionality for SDS management, environmental reporting, hazardous material tracking, and automated documentation to satisfy regulatory requirements while reducing administrative burden.

Q: What deployment options are available for process manufacturing ERP solutions?

A: Today’s manufacturing ERP softwares are available in cloud-based, on-premises, and hybrid deployments. Each option offers different advantages in terms of implementation speed, customization capabilities, IT resource requirements, and total cost of ownership.

Q: How does visual manufacturing ERP software improve production visibility?

A: Through customizable dashboards, real-time production monitoring, and integrated analytics, modern production ERP software provides unprecedented visibility into manufacturing operations, enabling faster decision-making and continuous improvement.

Q: What integration capabilities should manufacturing pro ERP systems include?

A: Look for systems with robust API libraries, pre-built connectors to common platforms, EDI capabilities for supplier and customer communication, and IoT integration for equipment monitoring to create a truly connected manufacturing environment.

Q: How long does it typically take to implement process manufacturing ERP software?

A: Implementation timelines vary based on company size and complexity, but typically range from 3-6 months for mid-sized organizations to 9-12 months for larger enterprises with multiple facilities or complex requirements.

Don’t let outdated systems limit your manufacturing potential. Contact MIE Solutions today to discuss how our process manufacturing ERP software can transform your operations and drive sustainable growth in today’s competitive landscape.