Without robust production scheduling software, manufacturing businesses face cascading challenges:

Successful Solutions

Save time and increase the accuracy of estimating with MIE Trak Pro’s quoting functionality which allows you to personalize formulas, track win/loss, and create quotes based on true costing data.

Learn more

Take your quote and create a Sales Order in just a few clicks. Sales Orders can be created from an RFQ, Quote, PDF, EDI, and more—depending on your team’s workflow.

Learn more

Gain insights into your production environment with MIE Trak Pro’s Work Order module. See all the information you want related to production in real-time.

Learn more

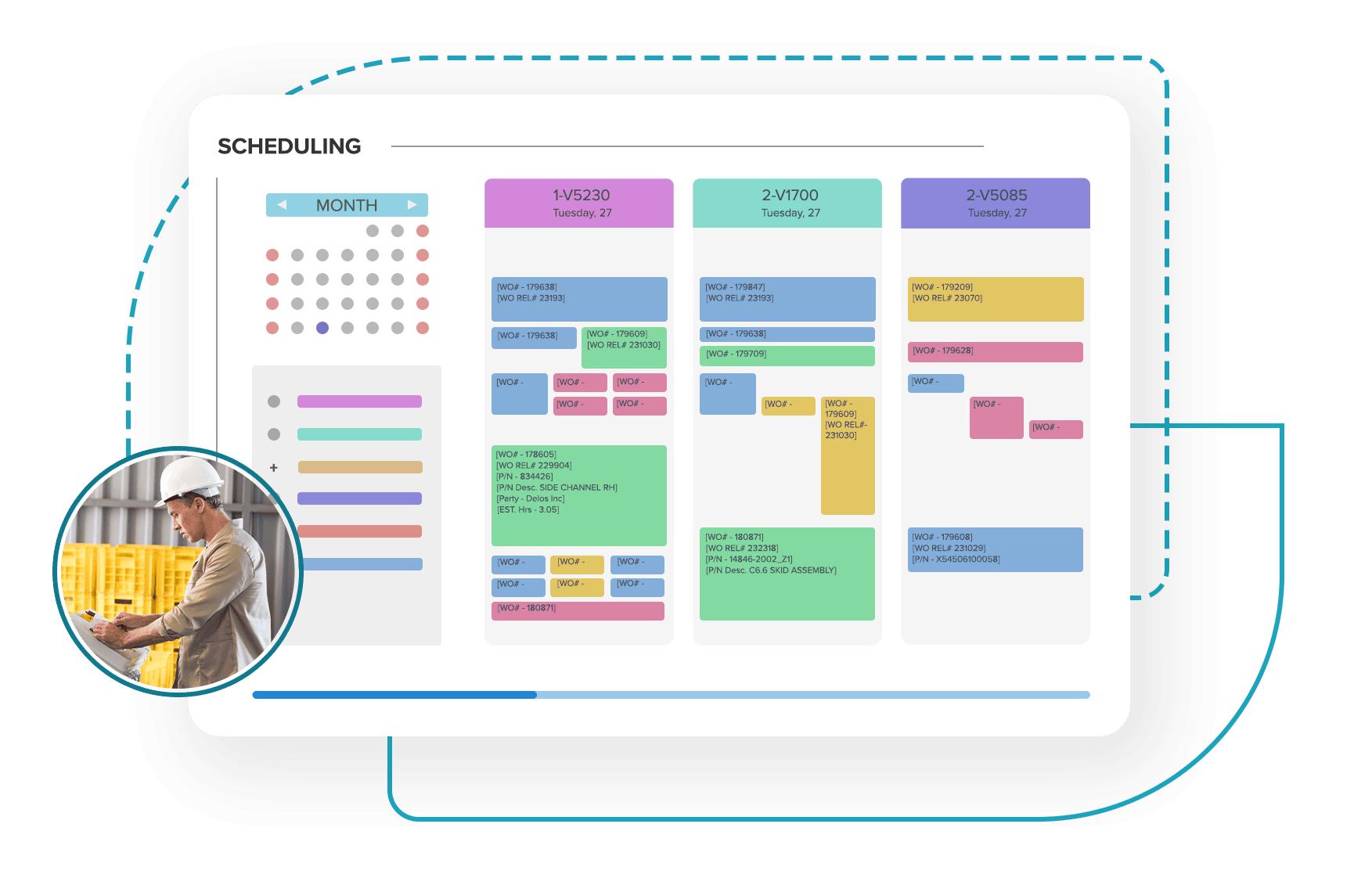

Schedule production quickly and accurately with forward finite, backward infinite, and calendar-based drag-and-drop scheduling. Take the guesswork out of scheduling employees and machines to jobs.

Learn more

Make purchasing easy and efficient with MIE Trak Pro’s Purchasing module. Order material based on MRP forecasting, min/max reorder points, production demand, and more.

Learn more

Track your inventory and the information that matters to you, including lot number serialization, locations, remnants, WIP, non-netted, consignment, and more.

Learn more

MIE Trak Pro’s built-in quality management system (QMS) allows you to accurately track Corrective and Preventive Action Requests (CPAR), non-conformance, RMAs, and more to pass QC audits with ease.

Learn more

Drive intelligent business decisions by using any of MIE Trak Pro’s standard reports or create personalized queries to get answers to the questions most important to you.

Learn more

Use MIE Trak Pro’s Kiosk module to track real-time job progress and employee clock-in (without the need for paper timesheets). Shop floor employees can see their schedule, view documents, issue material to jobs, create PO requests, and more.

Learn more

Integrate your accounting practices through MIE Trak Pro. Manage G/L Accounts, journal entries, reports, and cash flow projections, in addition to other critical accounting capabilities.

Learn moreA customer places a new order for 50 stainless steel enclosures, due in three weeks. The production manager has to balance this order with existing jobs to prevent bottlenecks. Without advanced scheduling software, this becomes a complex puzzle with costly consequences if solved incorrectly.

MIE Trak Pro’s Production Scheduling Software organizes your workflow from start to finish:

Balance workload across all resources while accounting for machine capabilities, labor availability, and maintenance schedules. Visualize capacity constraints in real-time to prevent bottlenecks before they occur.

Automatically sequence jobs based on priority, due date, setup time reduction, material availability, and customer importance. Our algorithms optimize for multiple constraints simultaneously.

When priorities change—and they will—instantly see the ripple effects across your entire production schedule. Make informed decisions about which jobs to expedite and which to delay.

Intuitive Gantt charts allow production planners to easily modify schedules with simple drag-and-drop functionality. Color-coded status indicators provide at-a-glance schedule health.

Test different scheduling approaches before implementation. Evaluate the impact of adding overtime, redistributing work, or changing job priorities without disrupting your live schedule.

With margins razor-thin, your job shop needs to maintain the highest level of operational efficiency. MIE Trak Pro supports all major scheduling methodologies to match your specific business needs:

Pros

✓ Maximizes resource utilization

✓ Provides realistic completion dates

✓ Identifies capacity constraints early

Cons

× May push delivery dates beyond customer expectations

× Requires accurate setup and run time estimates

Ideal for: High-volume manufacturers with stable production environments

Pros

✓ On-time delivery focus

✓ Customer-centric approach

✓ Simplifies promise date calculations

Cons

× Can create unrealistic capacity requirements

× May require overtime to meet commitments

Ideal for: Custom manufacturers with strict delivery deadlines

Pros

✓ Highly flexible for changing priorities

✓ Easy to understand and implement

✓ Adapts to unexpected disruptions

Cons

× Less optimization than algorithmic approaches

× Depends on scheduler expertise

Ideal for: Job shops with highly variable work and frequent rush orders

Pros

✓ Streamlines workflow for similar products

✓ Reduces setup time between jobs

✓ Improves throughput for repetitive work

Cons

× Less flexible for custom one-off jobs

× Requires grouping similar products

Ideal for: Manufacturers with product families and repetitive production

To give you flexibility, an ERP that supports all four scheduling approaches is essential. The one you choose may change depending on your business type or the specific challenge in front of you.

MIE Trak Pro’s Production Scheduling Software doesn’t operate in isolation—it forms the nerve center of your manufacturing operations:

Automatically sync with inventory levels, bill of materials, routings, and customer order data to ensure schedules reflect real-world constraints and priorities.

Capture actual production times, scrap rates, and machine status in real-time to continuously refine and improve schedule accuracy.

Incorporate quality checks and testing procedures directly into production schedules to prevent quality issues from causing delays.

Connect scheduling with supplier lead times and material availability to prevent production disruptions due to parts shortages.

Choose the implementation approach that aligns with your IT strategy and operational needs:

– Rapid deployment with minimal upfront investment

– Accessible from anywhere with internet access

– Automatic updates and maintenance

– Scalable resources as your business grows

– Complete control over your data and security

– Customizable to your specific network environment

– No dependency on internet connectivity

– Integration with existing on-site systems

When manufacturers implement MIE Trak Pro’s Production Scheduling Software, the impact is immediate and measurable:

“The ease with which we can track and manage inventory, monitor production schedules, and analyze financial data has greatly enhanced our decision-making processes.”

— Qualified Metal Fabricators

The reality is that many U.S. manufacturers are constrained by inflexible schedules that are easily derailed by unexpected challenges—impacting customer satisfaction and profit margins.

MIE Trak Pro gives you a toolkit to meet your deadlines by balancing capacity and loading requirements across all open jobs, ensuring that machines and operators use their time optimally.

Contact us today to learn how MIE Trak Pro’s Production Scheduling Software can help you deliver on time, every time.