Metal fabricators operating without proper ERP systems face mounting pressures that directly impact their bottom line. ERP features can boost manufacturing efficiency by up to 30%—a significant advantage when margins remain tight and competition intensifies.

Your metal fabrication business confronts increasing demands to reduce costs, optimize operations, and respond quickly to market changes. Precise inventory tracking, production planning, and quality control determine whether you maintain profitability or struggle with inefficiencies. Manufacturing ERP systems centralize critical data, automate workflows, and provide real-time visibility across every operation. NetSuite serves over 24,000 global customers while Acumatica ranks as the fastest-growing ERP system, yet choosing the right solution depends entirely on your specific operational needs.

What if you could identify exactly which ERP capabilities matter most for your fabrication operations? This guide examines 15 essential ERP features that metal fabricators should prioritize when selecting a system. From inventory management through IIoT integration, we’ll explore how these capabilities address your unique challenges and deliver measurable benefits including improved productivity, cost savings, and data-driven decision-making.

Inventory Management

Inventory management determines whether your metal fabrication operation runs profitably or struggles with costly inefficiencies. Managing various materials—from raw stock to finished goods—requires more than basic tracking capabilities.

Inventory Management in ERP

Manufacturing ERP systems deliver comprehensive tools for tracking and controlling inventory throughout your production cycle. These modules extend far beyond simple counts, enabling metal fabricators to define and track inventory with unlimited physical, dimensional, and chemical attributes. Specialized ERP features allow viewing remnants (drops) alongside stock material in the same inquiry, providing complete visibility into available resources.

Manufacturing ERP systems offer customizable inventory inquiries that search by any attribute, including chemistry and mechanical test results. This detailed tracking proves critical in metal fabrication, where material specifications directly determine product quality and regulatory compliance.

Benefits for Metal Fabricators

ERP inventory management delivers significant advantages for metal fabricators. Real-time tracking and automated data collection dramatically improve inventory accuracy while reducing costs from overstocking and preventing production-halting stockouts.

Key benefits include:

- Prevention of emergency orders through automated reordering

- Reduction in carrying costs by optimizing stock levels

- Full traceability from receipt to delivery

- Ability to track serialized components and tie purchase costs to specific products

ERP systems designed for metal fabrication handle industry-specific challenges like tracking partial materials, managing remnants, and recording chemical compositions—capabilities that generic inventory systems simply cannot provide.

Real-Time Tracking Capabilities

Real-time inventory tracking stands as a fundamental advantage of manufacturing ERP systems. Barcode scanning and RFID technology enable instant material identification, eliminating manual entry errors. Mobile accessibility allows shop floor staff to update inventory data using handheld devices directly where work occurs.

These systems deliver automated alerts when inventory levels reach predefined thresholds, ensuring timely reordering decisions. Batch and lot tracking capabilities provide complete traceability throughout the manufacturing process—essential during quality audits or when addressing customer concerns about material specifications.

Shop Floor Control

Metal fabrication shops operate in constant motion—rush orders arrive unexpectedly, materials get delayed, and machines require shared time across multiple jobs. Without proper shop floor control, managing these daily challenges becomes nearly impossible.

Manufacturing ERP systems provide shop floor control capabilities that address these operational realities head-on.

Shop Floor Control in ERP

Shop floor control encompasses methods and systems that prioritize, track, and report against production orders and schedules. This functionality calculates work based on percentage of completion for each order and operation, providing valuable data for inventory valuations and materials planning.

For metal fabricators, shop floor control means immediate insight into resource status, labor allocation, machine usage, and material flow—all essential elements for optimizing production efficiency. Modern ERP systems integrate these capabilities to help identify inefficiencies, minimize waste, and improve profitability through real-time cost tracking. Metal fabricators can increase production output without necessarily expanding their workforce.

How It Enhances Production Visibility

Traditional manufacturing environments suffered from severely limited production visibility due to outdated manual tracking processes. Shop floor control changes this entirely.

ERP systems deliver unprecedented visibility through:

– Real-time dashboards showing machine performance and job status – Centralized platforms eliminating the chaos of multiple Excel files– Color-coded progress indicators displaying whether jobs are on time, at risk, or behind schedule– Live capacity overviews that immediately reveal where potential bottlenecks are forming

This enhanced visibility enables supervisors to identify potential backlogs or equipment issues before they escalate into critical delays. Teams can respond proactively rather than reactively to production challenges.

Use Cases in Metal Fabrication

Metal fabrication shops face constant changes—rush orders, variable material deliveries, and shared equipment demands. Shop floor control addresses these challenges by enabling fabricators to:

- Manage workflow directly from the office to shop floor, sending jobs instantly to production teams

- Track the location of every product, tool, or work-in-process part in real time

- Schedule jobs based on machine availability, preventing idle time

- Monitor lead times, production capacity, and on-time delivery performance

This visibility helps metal fabricators maintain accurate timeframes and minimize scrap, improving customer satisfaction through reliable delivery dates.

Production Planning and Scheduling

Production planning challenges plague metal fabricators daily. Rush orders arrive while machines run at capacity. Material deliveries get delayed. Customer deadlines shift unexpectedly. Without proper planning systems, these disruptions create chaos that impacts every aspect of your operation.

ERP Production Planning Explained

Production planning in ERP systems maps out all processes, resources, and steps involved in manufacturing – from forecasting demand to determining raw materials, labor, and equipment requirements. Planning provides an overview of what to produce, while scheduling creates a detailed timetable specifying exactly when each step will occur and which resources will be assigned.

For metal fabrication specifically, ERP streamlines this complexity through centralized data on what needs to be manufactured, when, and how. This centralized approach becomes essential since many fabricators manage shared equipment across production lines while balancing complex routings with shop floor constraints.

Why Planning Matters for Fabricators

After implementing an ERP, 90% of business respondents recognized improved operational productivity and efficiency. For metal fabricators, the benefits address core operational challenges:

- Enhanced efficiency – Detailed production planning reduces bottlenecks, minimizes costs, and keeps expenses on budget

- Improved resource allocation – Real-time data on resource utilization helps optimize allocation while minimizing waste and downtime

- Customer satisfaction – Planning ensures on-time product delivery, leading to higher customer satisfaction and repeat business

- Cost control – Accurate demand forecasting and efficient scheduling help avoid overproduction and minimize inventory costs

Scheduling Optimization Techniques

Metal fabrication typically involves high-mix, low-volume operations with complex routings. Advanced scheduling techniques become vital for managing this complexity:

Controlled-push scheduling delays material release until optimal times, reducing work-in-progress inventory that sits idle waiting for bottleneck resources.

Optimization algorithms consider factors like order priorities, lead times, and material availability to minimize setup times and reduce changeover costs.

Advanced production scheduling software helps fabricators handle the chaos of job shops by identifying constraints that move depending on the job mix, whether in bending, welding, or coating.

What if you could eliminate the guesswork from production scheduling? Proper ERP planning tools make this possible by providing the data and automation needed to respond quickly to changing demands while maintaining operational efficiency.

Quality Management

Quality management determines whether your metal fabrication business builds a reputation for excellence or struggles with costly recalls and dissatisfied customers. Precision matters when you’re working with materials where even minor deviations can compromise structural integrity and safety standards.

Quality Management in ERP

Manufacturing ERP systems provide integrated quality control modules that establish standardized operating procedures and alert you when issues arise. These modules eliminate errors common in manual processes while enhancing customer satisfaction and controlling costs. Quality management in ERP allows metal fabricators to monitor quality metrics throughout production—from raw material inspection through final testing.

Real-time data helps you quickly identify and address deviations, ensuring only products meeting specifications reach customers. This proactive approach delivers increased satisfaction, improved brand reputation, and reduced risk of recalls.

Ensuring Compliance and Standards

Metal fabricators operate under stringent regulatory requirements, including ISO, AS, TS, and QS standards. Modern ERP systems include features specifically designed to ensure adherence to these critical frameworks:

– Support for industry-specific standards – Global engines for international legal, tax, and financial compliance

– Management of compliance documentation – Detailed audit trails for regulatory inspections

ERP solutions automate compliance processes, reducing non-compliance penalties, legal issues, and reputational damage. The three main ISO standards relevant to metal fabrication include ISO 9001 (quality management systems), ISO 14001 (environmental management), and ISO 45001 (occupational health and safety).

Tools for Quality Control

Advanced ERP systems offer sophisticated quality control processes that address how metal fabricators approach quality assurance:

Statistical Process Control (SPC) and Statistical Quality Control (SQC) enable real-time monitoring of production processes, detecting variations that may indicate quality deviations. Automatic part qualification and rejection features streamline inspection workflows, reducing human error. Supplier quality tracking tools evaluate vendor performance, ensuring incoming materials meet specifications.

Centralized quality documentation management maintains inspection reports, certificates of conformity, and corrective action plans in one accessible location. This ensures traceability and simplifies regulatory audits. ERP-documented compliance systems provide essential protection against financial and operational risks that could otherwise devastate manufacturing operations.

Bill of Materials (BOM) Management

Metal fabricators understand that the Bill of Materials (BOM) serves as the essential “recipe” driving manufacturing success. This critical component determines whether your operation runs profitably or struggles with costly inefficiencies.

What is BOM in ERP

A Bill of Materials in ERP represents a structured list of all materials, components, and parts required to manufacture a product, along with their quantities, descriptions, and costs. This central document includes procurement instructions and serves as the DNA of your product. BOMs emerge through collaboration between engineers (who define quantities and routing) and cost accountants (who assign values to materials and labor). Manufacturing ERP systems centralize this information while applying access controls so different team members can view only the information relevant to their roles.

Managing Complex Assemblies

Metal fabrication involves complex, multilevel assemblies with numerous components. ERP systems handle these intricate structures effectively:

- Multi-level management of assemblies, BOMs, and operations in one place

- Support for phantom items that simplify complex BOMs by including sub-assemblies as single units

- Version control mechanisms that track changes and maintain revision history

ERP systems that support relationships between materials and operations prove most effective, enabling CAD/CAM integration. This integration allows components to be uploaded directly from CAD systems, eliminating duplicate work and reducing errors.

Benefits for Fabricators

BOM management through ERP delivers significant advantages for metal fabricators. It creates a single source of truth about product information, eliminating inconsistencies from multiple spreadsheets. Production planning improves through precise material requirements calculation, reducing the risk of stockouts or overordering. Quality control enhances by ensuring the right materials are used for each job.

Accurate BOMs drastically improve overall business performance. Even small improvements in BOM accuracy create substantial benefits—inaccuracies can result in 40% of procured items being incorrect, with profound profitability implications. For job shops operating on tight margins, this level of precision becomes essential for maintaining competitiveness.

Supply Chain Management

Supply chain disruptions can derail production schedules and erode profit margins for metal fabricators. Real-time visibility across your supplier network becomes essential when managing complex procurement requirements and tight delivery deadlines.

ERP Supply Chain Features

Manufacturing ERP systems extend beyond your facility walls through direct integration with supplier and logistics networks. Key capabilities include:

- Real-time visibility into orders, inventories, and deliveries across the entire supply chain

- Collaborative platforms for coordinating with partners and resolving issues proactively

- End-to-end transparency for greater efficiency and risk mitigation

- Automated purchase order scheduling to prevent material shortages

The ERP software market with supply chain management capabilities will reach USD 14.00 billion globally by 2025.

Procurement Optimization for Fabricators

Metal fabricators gain significant advantages through ERP-driven procurement optimization. Automated procurement processes reduce administrative costs and ordering errors while enhanced supplier relationship management enables just-in-time inventory practices.

Smart tools integrated within ERP provide procurement teams with enhanced visibility, facilitating collaboration among stakeholders and ensuring everyone works toward common goals. ERP systems help identify inefficiencies, minimize waste, and improve profitability—critical factors when managing multiple suppliers across various material types.

Reducing Lead Time Challenges

Long supplier lead times often create the biggest barriers to reducing overall production time. Your ERP system addresses this challenge through several approaches:

– Tracking supplier performance to identify which vendors cause delays – Offering real-time inventory monitoring to prevent stockouts

– Coordinating warehouse and production schedules to avoid bottlenecks

These capabilities enable metal fabricators to reduce lead times at every stage, ensuring reliable fulfillment of customer orders.

Customer Relationship Management (CRM)

Metal fabrication success depends heavily on maintaining strong customer relationships. Meeting precise client specifications determines whether customers return with future business—and in an industry where projects often involve complex custom work, relationship management becomes critical to profitability.

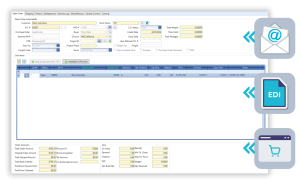

CRM in Manufacturing ERP

CRM modules in manufacturing ERP systems enable metal fabricators to centralize customer data and streamline sales processes. These specialized features automate lead tracking, quoting, and order management while providing a unified platform for all customer interactions. Designed specifically for the metal industry, these systems help manufacturers coordinate directly with distributors, track consumer demand levels, and manage shipping schedules. When you integrate ERP order management with CRM modules, fabricators gain detailed customer insights, enabling personalized approaches based on purchase history and preferences.

Improving Customer Satisfaction

Voice of the customer (VOC) management stands as a crucial element in metal fabrication. Listening through multiple channels—conversations, surveys, focus groups, and shop floor visits—helps identify customer needs and expectations. Fabricators who understand both external customers (who purchase products) and internal customers (within the company) accelerate their improvement journey. Offering tailored solutions based on unique requirements increases satisfaction and repeat business.

Order Tracking and Communication

Customer portals provided by modern ERP systems empower clients with access to order history, tracking information, and account management tools. These tools enable real-time order status updates, reducing customer inquiries. Proactive communication about potential delays builds trust and transparency throughout the order fulfillment process.

For metal fabricators handling multiple complex projects simultaneously, this visibility prevents the confusion that often damages customer relationships when deadlines shift or specifications change.

Financial Management

Financial visibility determines success or failure for metal fabricators operating with tight margins. Without accurate cost tracking and financial controls, your fabrication business risks underpricing jobs, missing profit opportunities, and making decisions based on incomplete information.

Financial Tools in ERP

Metal fabrication ERP systems provide essential financial modules including accounts payable, accounts receivable, general ledger, and collections capabilities. These tools offer unlimited history tracking, streamlined month-end processing, and detailed audit trails for complete financial transparency. Job costing functionality addresses the four critical components of metal fabrication costs: material expenses, direct and indirect labor, overhead allocation, and outside processing—all tracked precisely by sales order line.

Budgeting and Cost Control

Real-time cost tracking capabilities identify inefficiencies and eliminate waste before they impact your bottom line. Job costing features calculate exact project costs, accounting for labor, materials, equipment usage, and overhead expenses. This detailed cost visibility enables metal fabricators to analyze expense breakdowns, compare actual performance against estimates, and identify areas where profitability improvements are possible. These tools prevent the common fabrication pitfalls of underpricing bids and overcommitting on delivery promises—both critical for maintaining healthy margins.

Integration with Operations

Financial data becomes actionable when connected to operational information. This integration enables accounting teams to monitor cost per unit, track operating margins, and analyze revenue growth patterns. Manufacturers gain the ability to make informed decisions using accurate financial metrics that reflect current production realities. When properly implemented, ERP financial management becomes the foundation supporting both operational resilience and sustainable growth.

Asset Management

Metal fabricators manage dozens or hundreds of specialized tools and equipment pieces across their operations. Without proper tracking, a single misplaced cutting tool can halt production while workers search through the shop floor.

Tracking Equipment and Tools

Tool management within ERP systems enables systematic organization, tracking, and maintenance of equipment used to produce distinct items. This approach ensures the right tools are available, in the right condition, precisely when needed—even with hundreds or thousands of tools in circulation. Real-time tracking capabilities allow immediate location and status updates of every tool, significantly reducing search time and identifying process bottlenecks. Centralized systems also manage equipment certifications, training records, and documentation to maintain compliance.

Your shop floor operates more smoothly when everyone knows exactly where to find the right tooling. ERP systems eliminate the frustration of hunting for specific dies, fixtures, or cutting tools that could be anywhere in the facility.

Maintenance Scheduling

Proactive maintenance scheduling through ERP avoids costly unplanned downtime. Fabricators can extend tool life and avoid emergency repairs through preventative maintenance. Modern ERP systems coordinate maintenance windows with production schedules to minimize disruption. Above all, this helps bridge the gap between maintenance needs and production requirements. Predictive maintenance capabilities integrate sensor data and usage metrics to schedule upkeep prior to failures.

Equipment breakdowns during rush orders create expensive delays and frustrated customers. ERP maintenance scheduling prevents these disruptions by alerting you when machines need service before they fail.

Reducing Downtime

Unplanned downtime severely impacts metal fabrication operations—stalling production, causing missed deadlines, and increasing costs. Effectively scheduled maintenance typically improves asset utilization, reduces rework, and extends equipment lifespan. ERP systems automatically structure maintenance tasks based on operational schedules and real-time performance data, addressing issues proactively instead of reactively.

The difference between planned and unplanned maintenance often determines whether you meet delivery commitments or scramble to explain delays to customers.

Document Management

Paper-based document chaos plagues metal fabrication operations, creating bottlenecks that directly impact productivity and compliance. Document management capabilities within manufacturing ERP systems address these critical challenges while ensuring vital information remains accessible throughout your operations.

Centralized Document Storage

Metal fabricators juggling hundreds of customer specifications, quality certificates, and production records need systematic organization. Document management systems centralize all documents related to production, logistics, and accounting processes across your company. This digital approach creates a secure, organized repository for product development files, quality assurance documentation, purchasing records, and invoices.

What makes this particularly valuable for metal fabrication? These digital archives connect documents directly to customers, vendors, products, or specific events—making them instantly retrievable for accounting and compliance purposes. No more hunting through filing cabinets when auditors arrive or customers request certification documentation.

Version Control and Compliance

Document errors can prove costly in metal fabrication, where specifications change frequently and quality standards remain strict. Modern ERP systems implement robust version control capabilities that track every document change, including originator identification and timestamps. This transparency prevents errors while enabling quick clarification of interdepartmental queries.

Metal fabricators face potential product liability issues that require immediate access to historical documentation. Tamper-proof long-term archiving prepares fabricators for potential lawsuits by providing immediate access to crucial documentation—from batch numbers to production system temperature curves. Visual status indicators make it effortless to identify pending, released, checked out, expired, or missing documents.

Access Control Features

Not everyone needs access to every document. Role-based access control ensures appropriate security by assigning users to specific roles with tailored permissions. This approach restricts sensitive information access while allowing designated team members—whether internal employees, customers, or suppliers—to view necessary documents.

Color-coding features indicate approval process status, clearly showing whether documents are approved, rejected, or pending review. This visual approach eliminates confusion and keeps workflows moving efficiently through your organization.

Human Resource Management

Managing a skilled workforce presents unique challenges for metal fabricators. Finding qualified welders, maintaining certifications, and coordinating shift schedules across complex production demands can make or break your operational efficiency.

HR Modules in ERP

Manufacturing ERP systems include HR modules that handle the complete employee lifecycle—from recruitment and onboarding through performance management and termination. These modules centralize employee information and HR processes in one system, becoming increasingly important as companies focus on career development and employee experience. HR modules maintain accurate records while providing secure access to designated personnel through employee self-service portals.

Labor Allocation and Training

Metal fabrication requires specialized skills that can’t be easily replaced. ERP workforce management features track worker productivity and optimize shift scheduling. Certification tracking represents one of the most valuable capabilities—the system automatically monitors whether training and certifications remain current and alerts management when renewals approach. The system prevents scheduling uncertified employees for jobs requiring specific qualifications, maintaining both quality and compliance. ERP also identifies skill gaps where shortages might occur, enabling proactive training to avoid production delays.

What happens when your certified welder calls in sick and you have an aerospace job due tomorrow? ERP systems help you quickly identify alternative qualified personnel or adjust schedules to accommodate these real-world challenges.

Payroll Integration

Metal fabricators face complex payroll challenges that generic systems struggle to handle:

- Handling incentive pay and job-based labor tracking

- Managing various shift schedules

- Ensuring compliance with labor laws

This integration enables fabricators to reduce HR costs while improving shop floor efficiency through streamlined payroll, insurance, and compliance systems. The system handles the complexity so you can focus on production rather than administrative headaches.

Data Analytics and Reporting

Your metal fabrication shop generates mountains of data daily—from machine runtime to material usage. Data-driven decision making offers metal fabricators a clear competitive edge when properly implemented through robust ERP analytics features.

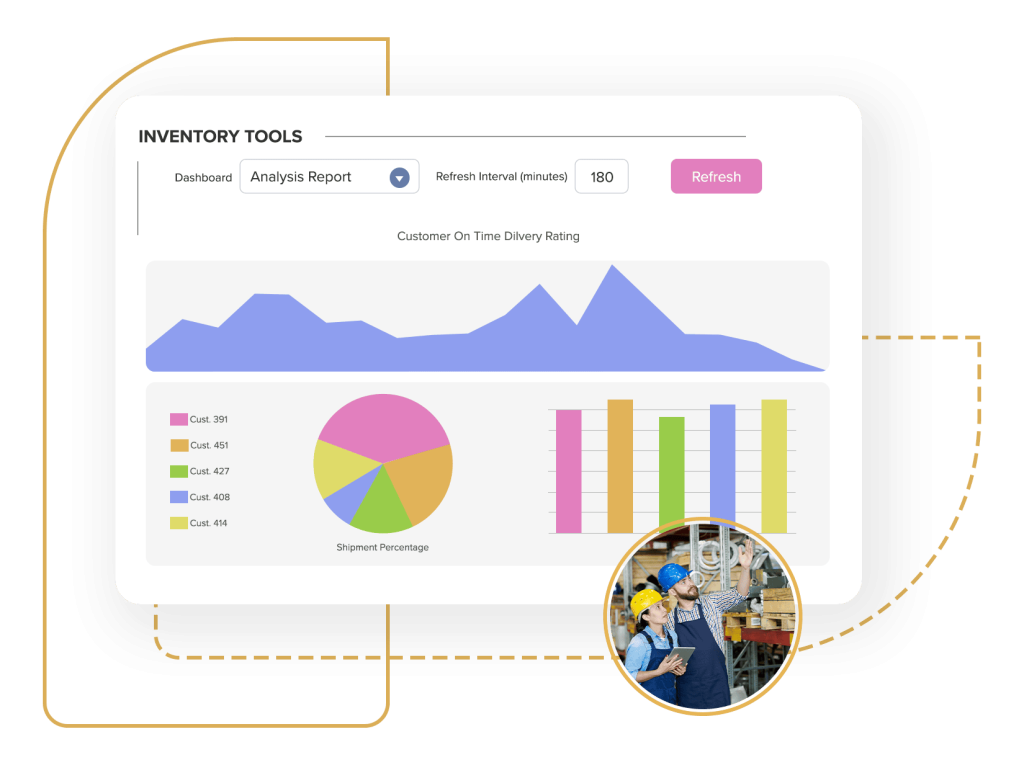

ERP Reporting Tools

Manufacturing ERP systems deliver powerful reporting capabilities that enable metal fabricators to analyze actual machine, material, and labor overhead tracked over time. These tools help improve the accuracy of costing and pricing while monitoring productivity at every step of operations. Tracking actual versus estimated run times and materials usage allows you to quickly identify trouble spots and implement corrective actions. ERP systems provide visibility into specific production resources—by employee, machine, or gauge—meeting the particular requirements of metal fabrication operations.

What if you could pinpoint exactly which jobs drain profitability? Detailed reporting reveals patterns that spreadsheets simply cannot capture, enabling data-driven pricing and operational improvements.

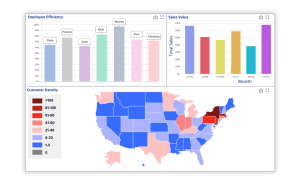

Real-Time Dashboards

Digital manufacturing dashboards serve as intuitive visual interfaces displaying critical production metrics in real-time. These dashboards convert complex data into easy-to-understand graphics, giving managers a quick snapshot of business operations. Rather than waiting for end-of-month reports, dashboards answer immediate questions:

- What is the current state of our operations?

- What happened recently in production?

- What emerging trends require attention?

To learn more about how MIE Trak Pro delivers dashboard capabilities for metal fabrication, contact their team for a personalized demonstration.

Predictive Analytics for Manufacturing

Predictive analytics uses historical data, statistical algorithms, and machine learning techniques to forecast outcomes. For metal fabricators, this means anticipating equipment failures and scheduling maintenance just in time—minimizing downtime and reducing emergency repair costs. These advanced capabilities help optimize inventory levels through more accurate demand forecasting. The global market for predictive analytics is projected to grow at a compound annual growth rate of 24.1% by 2030, highlighting its increasing importance in manufacturing environments.

Smart analytics identify trends before they become problems, enabling proactive management instead of reactive firefighting.

Product Lifecycle Management (PLM)

Image Source: Neel SMARTEC

PLM systems work alongside ERP to complete your manufacturing technology foundation. ERP focuses primarily on financial activities and order management, while PLM concentrates on product design, development, and quality.

Managing Product Data

Metal fabricators need a central repository for all engineering and manufacturing data—PLM creates this “single source of truth”. The system stores, shares, and manages bills of material while simplifying collaboration across teams. Custom fabricators find particular value when PLM helps sales and estimators identify previously fabricated parts similar to current quotes, allowing them to apply past experience to new projects.

Engineering Change Control

Engineering changes happen frequently in metal fabrication. PLM brings structure to these processes by enabling products to be defined, released, and revised through controlled workflows. Key capabilities include product versioning, enhanced release functionality, and engineering change orders. Fabricators can document changes, assess their impacts, and apply modifications systematically throughout a product’s lifecycle.

Lifecycle Visibility

Many believe PLM applies only to companies making their own products—custom fabricators benefit equally from lifecycle management. PLM integration with ERP creates extended visibility and control, generating synergy where “the sum is greater than the individual parts”. This integration reduces data replication while making production costs clearly visible to all stakeholders.

AI and Machine Learning Integration

Image Source: Intelliarts

Artificial intelligence and machine learning capabilities in metal fabrication have moved beyond experimental stages, with 70% of manufacturers already implementing some form of AI into their operations. The AI manufacturing market is projected to reach $16 billion by 2027 at a 31.22% CAGR.

AI in Manufacturing ERP

Modern manufacturing ERP platforms integrate AI/ML algorithms to help metal fabricators work smarter, not harder. These intelligent systems analyze production data, automate routine tasks, and provide actionable insights that directly impact your bottom line. More than a third of businesses are using AI for various operational tasks. For metal fabricators, AI-powered ERPs can analyze proposal and sales correlations, helping you identify ideal customer profiles based on order characteristics and timing.

Predictive Maintenance

Predictive maintenance delivers game-changing results in metal fabrication environments. Smart data management enables AI algorithms to identify equipment failures before they occur, reducing machine downtime by 30-50% while extending useful equipment life by 20-40%. Sensors monitor vibration, temperature, and pressure data that AI analyzes to schedule maintenance precisely when needed.

What if you could prevent that expensive laser cutter breakdown before it happens? This proactive approach eliminates the chaos of emergency repairs and keeps your production schedule on track.

Smart Process Optimization

AI-driven process optimization streamlines workflows and boosts efficiency across your fabrication operations. Intelligent scheduling algorithms optimize production sequences based on current shop conditions. To learn how MIE Trak Pro’s AI capabilities can enhance your metal fabrication operations, request a personalized demonstration of their advanced manufacturing ERP features.

IIoT and Smart Factory Integration

IIoT represents the next step in manufacturing evolution for metal fabrication operations seeking greater efficiency and production visibility.

Understanding IIoT in Metal Fabrication

The Industrial Internet of Things consists of interconnected devices that cooperate in real-time, exchanging data between machines, systems, and people. Through sensors and advanced communication technologies, IIoT enables performance monitoring, resource management, and production process optimization. The global IIoT market reached USD 194.40 billion in 2024 and is projected to increase to USD 286.30 billion by 2029.

For metal fabrication specifically, IIoT drives smart manufacturing by enabling real-time data exchange between machines and sensors. This connectivity transforms traditional manufacturing environments into responsive, data-driven operations.

Connecting Machines to ERP

Integration between IIoT devices and ERP systems creates secure data flow using communication technologies like MQTT or OPC UA protocols. This connection eliminates blind spots that prevent managers from gaining a clear picture of shop performance.

Bi-directional data flow from shop floor machines to ERP systems allows fabricators to adjust programs and optimize workflow in real-time. Machine-to-ERP integration closes the loop between planning and execution, enabling more accurate quoting based on actual performance rather than estimates. This represents a fundamental shift from reactive to predictive manufacturing management.

Advantages for Metal Fabricators

IIoT-ERP integration delivers measurable advantages for metal fabrication operations:

– Real-time monitoring reduces unexpected breakdowns and unplanned downtime by 30-50%– Smart inventory management tracks stock levels and predicts demands automatically

– Automated reordering triggers when inventory falls below predetermined thresholds– Enhanced quality control through continuous monitoring of temperature, pressure, and humidity

These capabilities enable metal fabricators to respond proactively to production challenges while maintaining consistent quality and delivery performance. The integration creates a foundation for continuous improvement and operational excellence.

Comparison Table

When evaluating ERP systems for your metal fabrication business, comparing key capabilities across all essential features helps you make an informed decision. This comparison highlights how each feature contributes to operational efficiency and business growth.

| Feature | Key Capabilities | Primary Benefits | Integration Aspects |

| Inventory Management | – Real-time tracking and automated data collection- Customizable inventory inquiries- Material attribute tracking | – Improved inventory accuracy- Reduced carrying costs- Prevention of emergency orders | – Barcode/RFID integration- Mobile accessibility- Automated alerts |

| Shop Floor Control | – Real-time job status tracking- Work percentage completion calculation- Resource status monitoring | – Enhanced production visibility- Proactive bottleneck prevention- Improved workflow management | – Direct office to shop floor connection- Real-time dashboards- Machine performance tracking |

| Production Planning | – Demand forecasting- Resource requirement planning- Detailed scheduling | – 90% improved operational efficiency- Reduced bottlenecks- Better resource allocation | – Centralized data management- Integration with shop floor constraints- Optimization algorithms |

| Quality Management | – SPC/SQC monitoring- Automated inspection workflows- Compliance documentation | – Reduced non-compliance penalties- Improved customer satisfaction- Minimized recalls | – ISO standards integration- Audit trail tracking- Supplier quality systems |

| BOM Management | – Multi-level assembly management- Version control- Cost tracking | – Single source of truth- Improved production planning- Enhanced quality control | – CAD/CAM integration- Engineering collaboration- Cost accounting connection |

| Supply Chain Management | – Real-time order tracking- Automated procurement- Supplier performance monitoring | – Reduced administrative costs- Minimized waste- Improved lead times | – Supplier network integration- Logistics coordination- Warehouse management |

| CRM | – Lead tracking- Quote management- Order processing | – Improved customer satisfaction- Streamlined sales processes- Better customer insights | – Customer portals- Order tracking systems- Marketing automation |

| Financial Management | – AP/AR management- Job costing- General ledger | – Precise cost tracking- Better margin control- Improved decision-making | – Operations data integration- Real-time cost tracking- Accounting system connection |

| Asset Management | – Equipment tracking- Maintenance scheduling- Tool management | – Reduced downtime- Extended equipment life- Better resource utilization | – Sensor data integration- Maintenance systems- Production scheduling |

| Document Management | – Centralized storage- Version control- Access control | – Improved organization- Better compliance- Reduced paper waste | – Role-based access- Digital archiving- Workflow automation |

| HR Management | – Employee lifecycle management- Certification tracking- Labor allocation | – Streamlined HR processes- Better compliance- Improved productivity | – Payroll systems- Training management- Self-service portals |

| Data Analytics | – Real-time reporting- Dashboard visualization- Predictive analytics | – Better decision making- Improved visibility- Proactive problem solving | – Machine data integration- Business intelligence tools- Statistical analysis |

| PLM | – Product data management- Engineering change control- Version tracking | – Single source of truth- Better collaboration- Controlled changes | – ERP system integration- Engineering systems- Document management |

| AI/ML Integration | – Predictive maintenance- Process optimization- Automated analysis | – 30-50% reduced downtime- 20-40% extended equipment life- Improved efficiency | – Sensor networks- Data analytics platforms- Machine learning systems |

| IIoT Integration | – Real-time monitoring- Machine connectivity- Automated data collection | – Reduced breakdowns- Smart inventory management- Enhanced quality control | – MQTT/OPC UA protocols- Machine-to-ERP connection- Sensor networks |

Each feature addresses specific operational challenges while contributing to your overall manufacturing efficiency. The integration aspects show how these capabilities work together to create a unified system that supports your entire operation from quote to delivery.

Conclusion

Selecting the right ERP system with these 15 essential features will undoubtedly transform metal fabrication operations. Each feature addresses specific challenges faced by manufacturers while working together as an integrated system to drive overall efficiency. Metal fabricators who implement comprehensive ERP solutions typically experience significant improvements across their entire operation—from shop floor productivity to financial performance.

Companies that invest in advanced ERP capabilities gain substantial competitive advantages through enhanced visibility, streamlined processes, and data-driven decision-making. Additionally, modern features like AI, machine learning, and IIoT connectivity prepare metal fabrication businesses for future manufacturing trends, ensuring long-term viability in an increasingly digital marketplace.

The journey toward operational excellence begins with understanding which ERP features matter most for your specific metal fabrication needs. Subsequently, you can evaluate various systems based on how effectively they deliver these capabilities within your budget constraints. MIE Trak Pro offers extensive capabilities specifically designed for metal fabricators—we encourage you to learn more about how their purpose-built solution addresses the unique challenges of metal manufacturing operations.

Therefore, whether you manage a small job shop or oversee a large manufacturing facility, implementing an ERP system with these essential features will help you optimize resources, reduce costs, and deliver superior products to your customers. The initial investment certainly pays dividends through improved efficiency, better customer satisfaction, and increased profitability—all critical factors for success in today’s competitive manufacturing landscape.

FAQs

Q1. What are the key features to look for in an ERP system for metal fabrication? Essential features include inventory management, shop floor control, production planning, quality management, and bill of materials (BOM) management. Other important capabilities are supply chain management, financial tools, asset tracking, and data analytics.

Q2. How can an ERP system improve efficiency for metal fabricators? An ERP system can boost efficiency by providing real-time visibility into operations, automating workflows, optimizing resource allocation, and enabling data-driven decision making. This can lead to reduced costs, improved productivity, and better quality control.

Q3. What are the benefits of integrating AI and machine learning in manufacturing ERP? AI and machine learning integration can enable predictive maintenance to reduce equipment downtime, optimize production processes, and provide intelligent insights for better decision making. This can result in 30-50% reduced downtime and 20-40% extended equipment life.

Q4. How does an ERP system help with quality control in metal fabrication? ERP quality management modules provide tools for statistical process control, automated inspection workflows, and compliance documentation management. This helps ensure adherence to industry standards, reduces non-compliance risks, and improves overall product quality.

Q5. What should metal fabricators consider when selecting an ERP system? Metal fabricators should consider factors like industry-specific features, scalability, integration capabilities, ease of use, and vendor support. It’s important to evaluate multiple systems, conduct trials, and choose a solution that best aligns with the company’s specific needs and growth plans.